Does the shop retain right of first refusal, or is moonlighting A-OK?

Way back when, torque specs didn’t exist. Oh, mechanics were familiar with busted fasteners. Prior to torque wrenches, factory tools often had handles of specific lengths, with the understanding that “cheater pipes” were not to be used and that an average man of average strength could use the tool to get critical fasteners tight enough. But a tool to accurately measure torque wasn’t invented until the 20s and weren’t in common use until World War II. Did you know Walter P. Chrysler was actually the guy who invented beam-style torque wrenches? (Yes, THAT Chrysler!) In professional shop applications all across America, the de facto tool for tightening fasteners to spec is the clicker-style torque wrench. But beam-types have a few advantages that keep them relevant, even today. If your arsenal doesn’t include one (even as a backup), you might want to think about acquiring one. Here’s why.

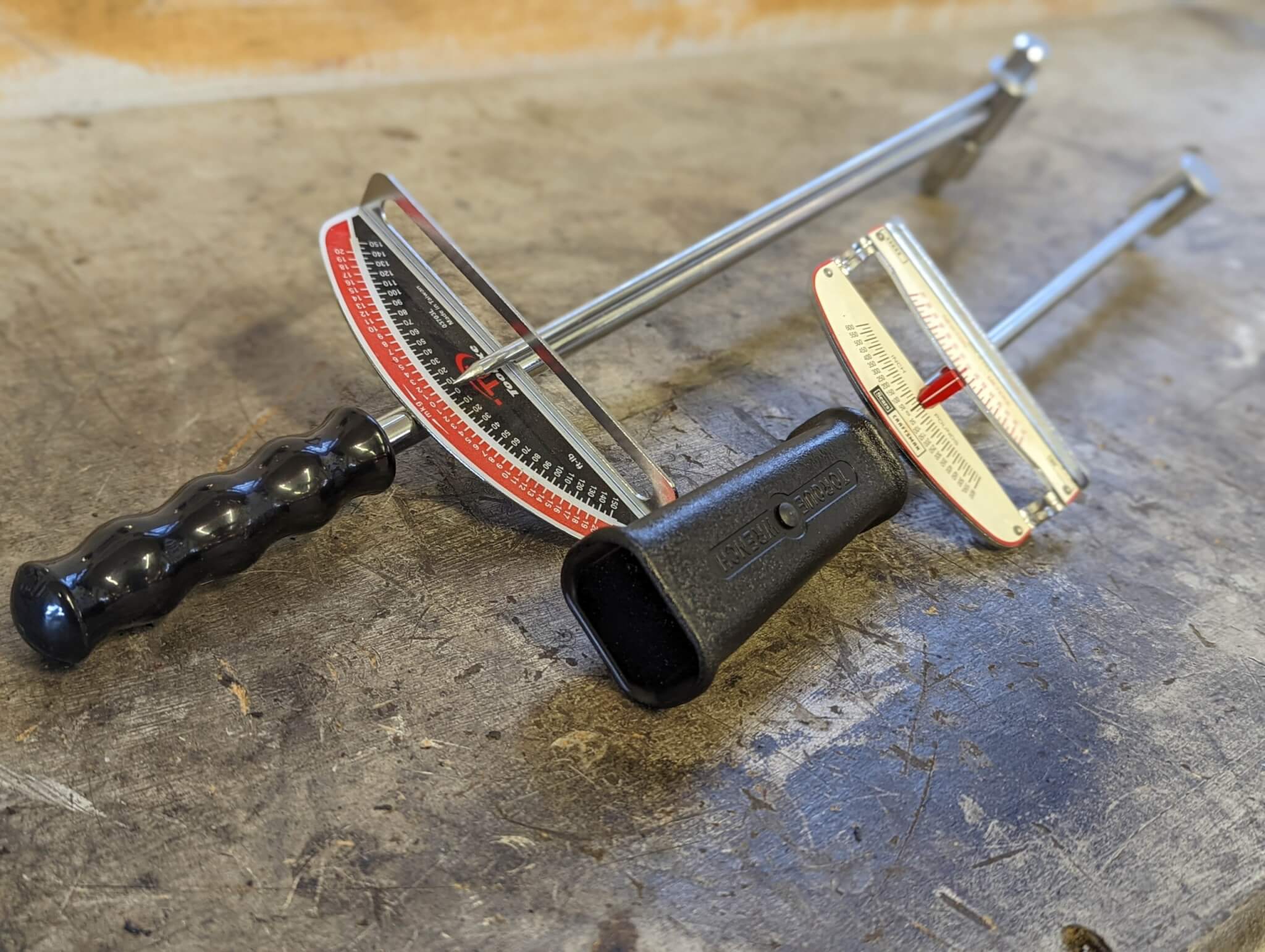

This old thing has torqued countless fasteners over the years. It could die tomorrow and it wouldn’t owe me nothin’. Photo by Lemmy.

A high-quality beam-style torque wrench is not a particularly pricey item when stacked up next to a comparable clicker-type. One of my old beam wrenches is older than I am. Amortized over its service life, the cost was miniscule.

Part of the reason they’re inexpensive is that they have no real moving parts to wear. That also makes them tougher. Drop a clicker-torque wrench, and you just made an expensive mistake requiring recalibration. Drop a beam-style wrench, and all ya need to do is make sure the pointer is still pointing at zero. Since the entire thing works off the deflection of the wrench relative to the pointer, there’s no real way to mess it up in a real-world shop setting—steel’s springiness is pretty much constant.

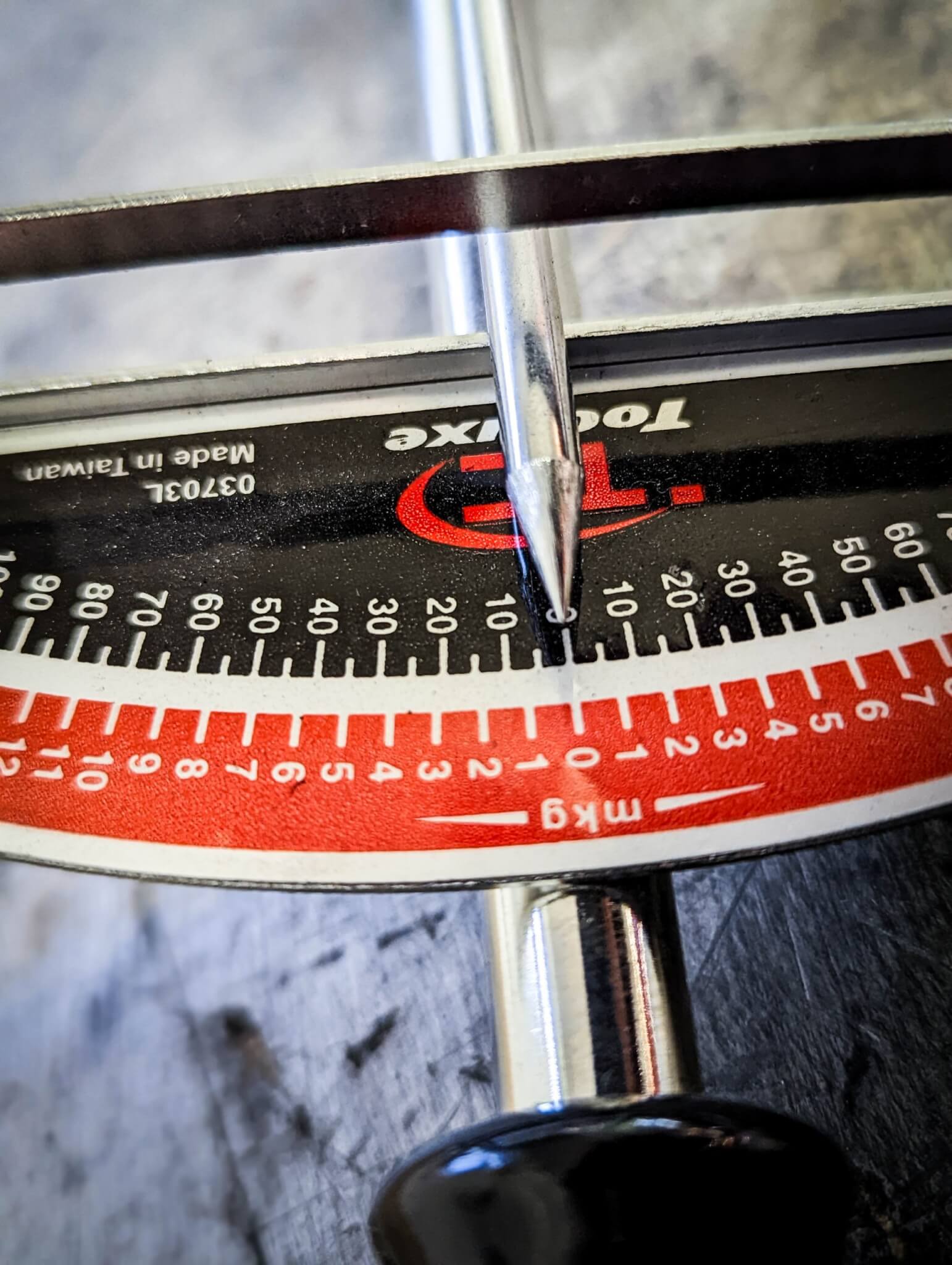

Calibrated correctly. And if it’s not, a simple adjustment is all it takes to make it right. Photo by Lemmy.

This is sort of related to the last point. Unlike clickers, beam-type torque wrenches don’t need to be recalibrated periodically. Do you really want to find out that your clicker was improperly calibrated after you bust a cylinder head bolt or crack an expensive casting?

You can just put it away when you’re done. Beams don’t need any special treatment. Your clicker? Best relax that spring and set it back to zero if you want it to stay accurate.

Your grip is more uniform using the beam-style. Some wrenches have a handle that’s “pinned” into the end of the wrench and it can wobble. Proper use dictates the floating handle not be resting against the body of the wrench, meaning the effect of your hand placement along the body of the wrench is always minimized if you are using the tool correctly, leading to smaller torque variances between fasteners. A clicker usually just has a handle you’re supposed to grab and that’s that.

Here you can see one of the “floating” handles. By securing the handle to the wrench with a pin, consistent operation is virtually assured. Photo by Lemmy.

Clickers have their strong points, certainly—they can be used in places where the beam’s scale can’t be read, and the tactile and audible feedback can certainly be helpful in tight quarters. However, if you need a backup (or even just a second to check the accuracy of your main tool!), a beam-style torque wrench is definitely a workable option worthy of consideration.

Engine oil is a lubricant, but that’s not what the task’s title is referencing.

Every tech has a story. What’s yours?

What does your shop use? Where are you? Can you help us make a map?